Brief Introduction:

Model: UG-6060-4R

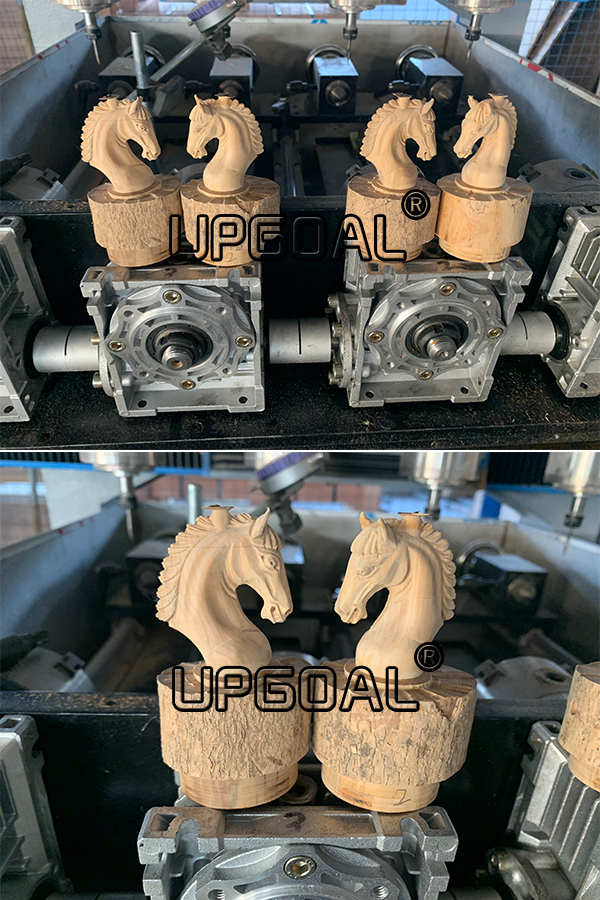

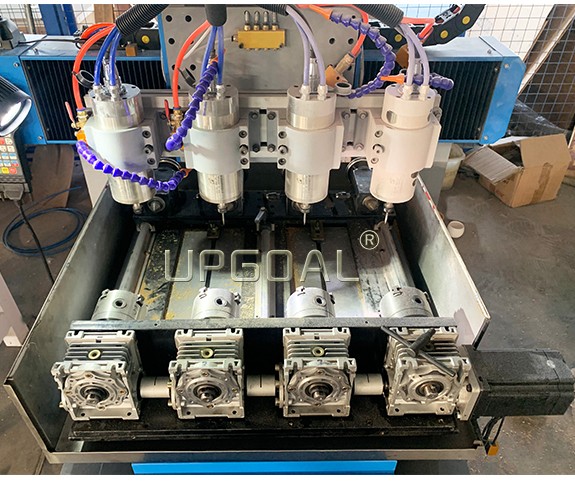

One Z with 4 pcs 2.2kw spindles

4 pcs rotary axis, diameter 80mm

DSP offline control system

Hybrid servo motor driver

Stainless steel water slot cooing

Applications

Industry application: Wood work, Advertising Sign&Mark, Acrylic Cutting, Advertising plate, Led Lamp.

Applicable material: Wood, Aluminum sheet, aluminum composite panel, dual-color plate, Mdf, Cristal plate, artifical marble and other metal and non-metal materials.

Working Method: 3D embossment engraving, 2D engraing and Cutting, Bottom Milling.

Features

1. Cast iron structure for machine bed/working table/gantry/Z-axis Stable Running with less Vibration.

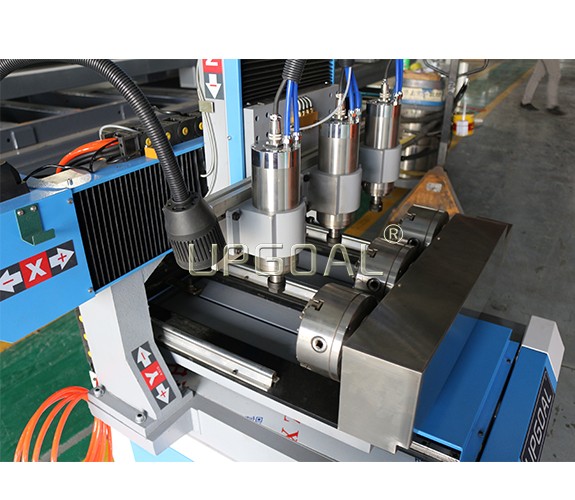

2. One Z-axis with 3/4 pcs spindle heads, and 3/4 pcs rotary axis, diameter 80mm, length 600mm, can for3/ 4pcs cylinder engraving at one time, much improving the working efficiency. And, each rotary axis with independent reduction gear type stepper motor, during working, the other ones can do continus working if one failure.

3. Each head with 2.2 kw water cooling spindle, ensuring the fine engraving is more smoothly and clear.

4. XYZ three axis are with Hiwin Taiwan linear square guide rail and block, TBI lead ball screws transmission for all axis, durable running with high accuracy.

5. DSP offline control system with USB interface which is completely off from computer. More Humanized design with Simple and Convenient Handle type operation.With pre-calculation rule, fully excavating potentialities of motors. Enable high processing speed, synchronization of curve and straight line, more perfect curve working and Spindle startup and stop automatically.

6. China Leadshine hybrid servo motor and hybrid servo driver H2-758 for XYZA-axis, compared with the stepper motor, ensuring high speed and precision working.

7. Stainless steel water slot cooling system, ensuring the processing hard metal & stone.

8. Auto lubrication system, convnient using.

9. Dust-Proof design for XZ-axis, protect the guide rail and gears pinon racks from the Dust&Dirt, help to ensure machine working performance.

10. With rationalized placement of the electronic parts. Optimized heat dissipation effect. Adopt high quality electronic parts, minimizing fault rate, Adopt high flexible cable and imported electronic parts, electrical design of whole machine is complied with the CE standard.

11. Favorable compatibility with various CAM softwares such as Type3/Artcam/Mastercam/Caxa. With intelligent over limit protection function which can stop the mechanical collision due to unproper size given to the design.

12. With the function of Break-point memory,power failure resuming and automatic home/origin correction function, effectively ensure long time working precision.

Each head flat working area | 600*(X)mm*600(Y)mm*200(Z)mm |

4th axis rotary axis number | 3/4pcs |

Each rotary axis working area | 80mm*600mm |

Rotary axis table | Removable |

Spindle number & power | 4pcs, 2.2kw water cooling( ER20) |

Spindle speed | 0-24000rpm |

Inverter | Fuling |

Materials | Cast iron structure |

Moving type | Platform moving |

Guide rail | Linear square guide rail ( Hiwin, Taiwan) |

Transmission | Lead ball screw transmission( TBI, Taiwan) |

Driving mode | Leadshine hybrid servo motor driver( H2-758) for XYZA-axis |

Voltage | AC 220V, 50/60Hz, single phase |

Traveling speed | 8000mm/min |

Engraving speed | 6000mm/min |

Machine accuracy | 0.02mm |

Control system | DSP offline controller( RichAuto, A18E, 4 axis) |

Suitable software | Artcam, Type3, Ucancam V9,etc |

Carving Instructions | G code *Uoo *mmg *plt HPGL |

Running environment temperature | 0-45 ℃ |

Relative humidity | 30%-75% |

Tool calibration | Auto |

Lubrication system | Auto |

Certificate | CE |