Brief Introduction:

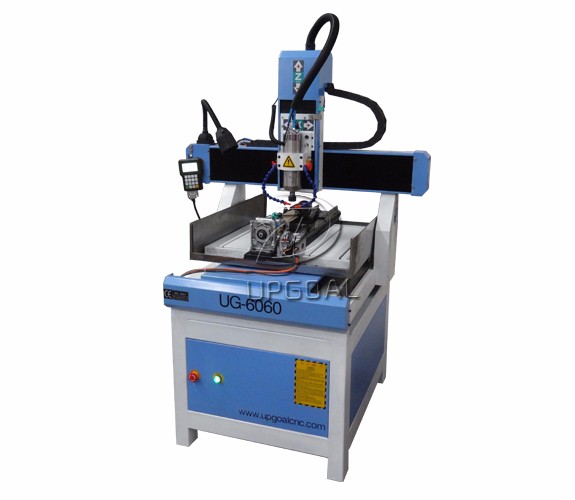

Model: UG-6090

Heavy duty type

600*900*250mm working area

DDCS 4axis offline controller

5.5kw water cooling spindle

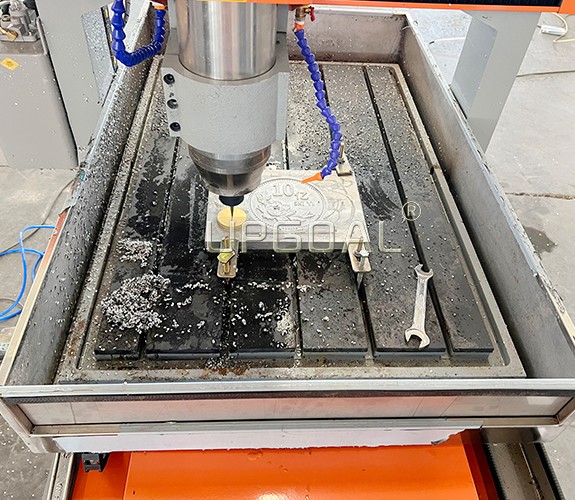

Oil mist & water cooling

Applications

Mould of Copper, Iron, aluminum, stainless steel. Shoe mould, mobile mould, Red Copper electrode, Building model, name tag, copper stamp.

Features

1.Heavy duty cast Iron structure( cast iron machine bed & working table & gantry & Z-axis) with vibration temper aging treatment ensures no deformation for long time.

2.Cast iron T slot working table with platform moving type. Durable without deformation enable positioning more precision .

3.Equipped with Hiwin Taiwan linear square guide rail for XYZ-axis, effectively improved the precision.

4.Three axis with precision TBI lead ball screw transmission ensure the engraving speed and accuracy.

5.High variable speed powerful 5.5kW water cooling spindle, big torque, longer life, strong cutting ability and continuous work for long time.

5.Powerful Leadshine hybrid servo motor and driver H2-758 for XYZ-axis, compared with the stepper motor, ensuring high speed and precision working.

6. DDCS V3 4 axis offline controller , with reasonable design, reliable control, easy operation, 17 keys can complete daily offline control operations, and supports the highly versatile FANUC compatible G command set

7.Rationalized placement of the electronic parts. Optimized heat dissipation effect. Adopt high quality electronic parts, minimizing fault rate.

8. With both oil mist cooling and stainless steel water slot cooling system, ensuring the cooling for the metal & hard materials.

9. 4th axis rotary axis, diameter 100mm, working length 600mm, reduction gear transmission.

10. With the function of break-point memory ,power failure resuming and automatic home/origin correction function.Effectively ensure long time working precision.

11. Working Pause, Speed adjust, Working depth adjust at any time while working. Preview the 2D&3D working result With simulation function. Variable Speed is suitable for various materials and industry.

12.Auto lubrication system, more convenient for machine lubricating.

13. Auto tools calibration, conveineint for working

Effective working area | 600(X)mm*900(Y)mm*250(Z)mm |

Feeding height | 250mm |

Materials | Heavy duty cast iron structure for machine bed & working table & gantry & Z-axis |

Working table | Cast iron T slot |

Moving type | Platform moving |

Guide rail | Linear square guide rail ( Hiwin, Taiwan) |

Transmission | Lead ball screw for XYZ-axis( TBI) |

Driving mode | Leadshine hybrid servo motor and driver (H2-758) |

Spindle motor | 5.5kw water cooling(ER25,HQD) |

Spindle speed | 18000-24000rpm |

Inverter | Fuling |

Voltage | AC 220V, 50/60Hz, single phase or AC 380V, 50/60Hz, three phases |

Traveling speed | 8000mm/min |

Engraving speed | 6000mm/min |

Machine accuracy | 0.02mm |

Control system | DDCS V3 4 axis offline controller |

Suitable software | Artcam, Type3, Ucancam V9,etc |

Carving Instructions | G code *Uoo *mmg *plt HPGL |

Running environment temperature | 0-45 ℃ |

Relative humidity | 30%-75% |

Cooling system | Oil mist cooling & stainless steel water slot cooling |

Tool calibration | Auto |

Lubrication system | Auto |

Certificate | CE |