Brief Introduction:

Model: UG-1500LW

Single wobble combined laser cleaning welding cutting

RelFar system

RayCUS 1500W fiber laser

HANLI industrial chiller

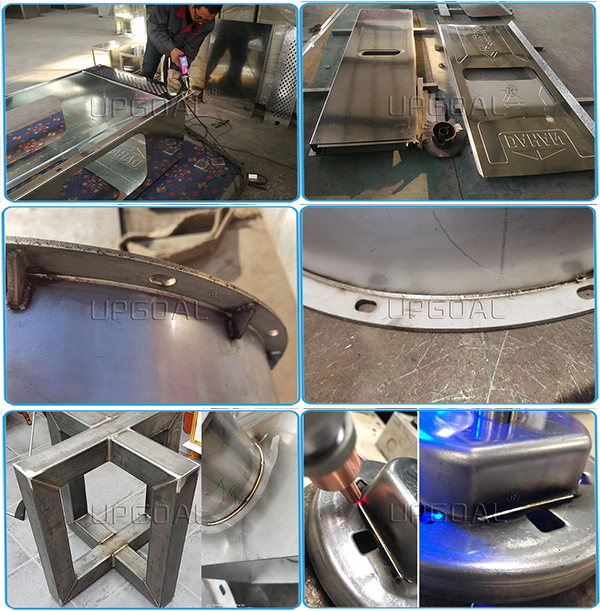

Applications

Handheld fiber laser welding machine, uses latest Raycus RFL-C1500 1500W fiber laser generator. It's equipped with China famous brand wobble weld head. The machines appear to laser equipment industries, fills in the blank of hand-held welding. It has the advantages of simple operation, beautiful welding beam and fast welding speed. Welding in thin aluminum,stainless-steel sheet, iron sheet, galvanized sheet and other metal materials can perfectly replace the traditional argon arc welding, electric welding and other processes.Handheld laser welding machine can be widely used in cabinets, kitchens, staircases, elevators, racks, ovens, stainless steel doors and windows guardrail, distribution boxes, stainless steel home and other industries complex and irregular welding process.

Handheld fiber laser cleaning machine is using surface decontamination capability of laser, using optical fiber transmission guide, so that cleaning can be in different position, the cleaning of different parts of an efficient, green, advanced cleaning technology, compared with chemical cleaning, without any chemicals and cleaning liquid; compared with mechanical cleaning, no grinding no stress, no supplies, minimum of matrix damage (artifacts and paintings, for a wide range of cleaning) (nuclear pipeline cleaning); the applicable object of the industrial laser cleaning machine is also more widely, to remove rust and paint, in addition to dirt, wafer surface treatment; And the cleaning degree of the handheld laser rust remover is high (to remove nano particles, the following pollution) technology has been applied in various fields (mold cleaning, cleaning and coating fighter). Widely applied in flat,curved and three-dimensional surface for work piece of elastic material and plastic with very small and deep holes.

Features

1 Intelligent welding head with temperature monitoring to monitor the protective lens for damage warning.

2 Galvanometer monitoring alarm

3 Protective lens for double protection

4 Focusing mirrors are drawer type for easy replacement

5. Welding head & cleaning head can be easy to changed.

6. Support Simplified, Traditional, Russian, English, Japanese, Korean, German, Portuguese, Spanish, Arabic

9 The gun head is light and easy to hold

10 Support process library preservation

11. Can provide customers with process parameter table of various silk and various plates

12. The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

13.The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful. Fast welding speed, 2~10 times faster than traditional welding.

14.Accurate laser cleaning for exact position and precise size. No maintenance and no consumables,dust-free,no chemicals,no pollution. Non-contact cleaning and no damage for substrate Extremely. Flexible operation for work pieces with complicated geometric construction can be realized by mechanized or hand-held laser cleaning head.

15.Easy operating need no training.

16. Safer, more environmentally friendly.

17. No consumables, small size, flexible processing, low operating and maintenance costs. Reducing daily maintenance costs and greatly increasing work efficiency.

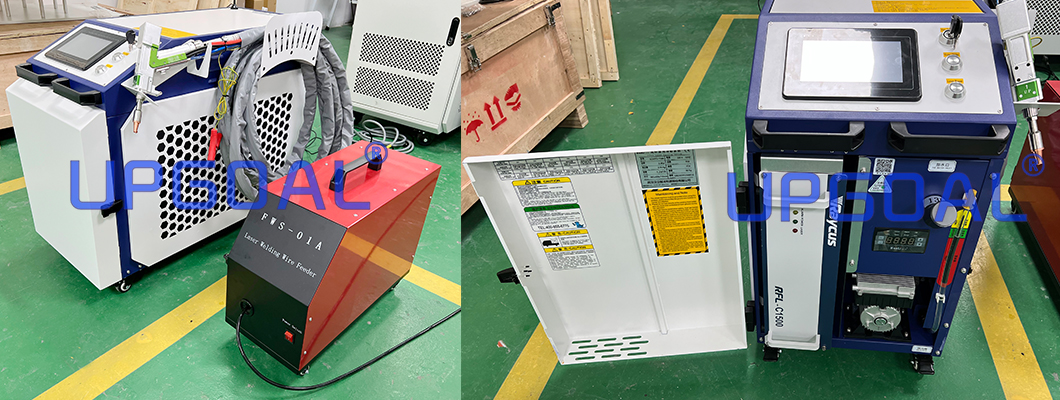

Main Parts

The built-in Hanli industrial laser chiller mainly provides cooling for the handheld laser welding machine. Cabinet-type design, after installing a handheld laser, it forms a light-duty mobile handheld laser welding all-in-one machine, with universal wheels at the bottom, which is easy to move and carry to the processing site of various application scenarios. Compared with traditional handheld laser welding machines, it is more convenient to install lasers and chillers without redesigning the cabinet.

Portable wobble handheld welding cleaning cutting head (RelFar) Light shape, economic deign, instead of fixed weling head, it offers so much welding convenience for welding big, or heavy or complex structure articles.

Special combined laser welding cleaning cutting system(RelFar): The software is easily operated as the mode of human-computer interface. Strong software function can be realized by simple touch screen.It has editable and memory functions.

With Wire Feeder Machine, in order to make the welding joint full and level and to meet the required mechanical strength requirements.

Laser Power | 1500W (Raycus brand,RFL-C1500 model) |

Laser Wave Length | 1070 NM±20nm |

Fiber Length | standard10M Maximum 15M |

Laser Pulse Frequency | 1-20HZ |

Pulse Width | 0.1-20ms |

Adjusted spot range | 0.1-3mm |

Minimum Welding pool | 0.1mm |

Collimating focal length | 50mm |

Focus length | 150mm |

Focus adjustment range | -10mm~+10mm |

Spot adjustment range | 0~5mm |

Gas source | Argon or Nitrogen,≤1Mpa |

Working mode | Continuous or modulate |

Welding cleaning head | Portable single wobble combined handheld welding cleaning head(RelFar, model: FWH20-S20A,0.72kgs) |

Welding cleaning system | Touch screen control panel(RelFar ) |

Beam quality | M2<1.2 |

Line width | <5nm |

Straight modulate | 0-5KHZ |

Welding speed range | 0~120 mm/s |

Cooling system | Water cooling, industrial water chiller, SCHYTJ-1500, Hanli |

Welding thickness recommendations | 0.5-4mm |

Welding gap requirements | ≤0.5mm |

Cleaning width | 0-80mm |

Working environment temperature | 15~35 ℃ |

Humidity range of working environment | < 70%No condensation |

Working Voltage | AC220V±10%, 50/60Hz, single phase |