Brief Introduction:

Model: UG-1390ML

300W ELC combined beam Co2 laser

RuiDa 6332M live focus system

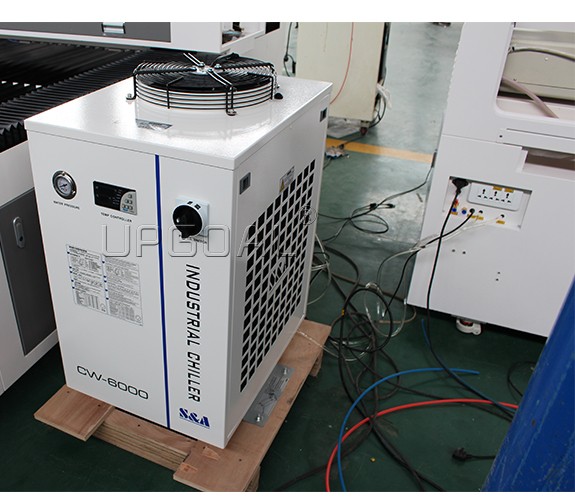

CW-6000 industrial chiller

1300*900mm

Stainless steel/carbon steel 2mm cutting ability

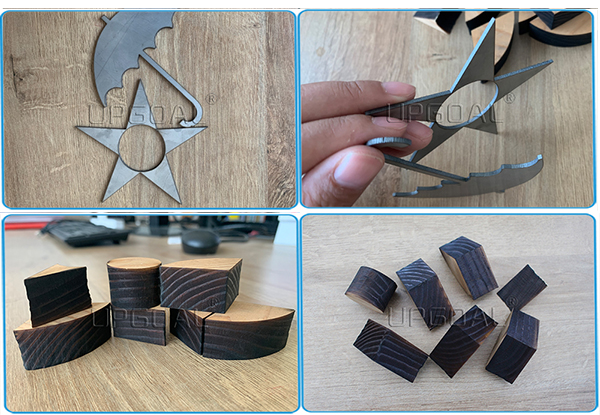

Applications

Applied to a certain of metal and non-metal materials Professional engraving/cutting such as stainless steel,carbon steel,wood,organic glass,plastic, cloth.

Widely used in the industry of Advertising, craft gift, shose, toys, garment, model, construction, package, paper and computerized embroidery &lipping.

Features

1. Welding machine bed with quenching treatment to remove away the stress .Milled by Large precision gantry milling machine ensured the accuracy.

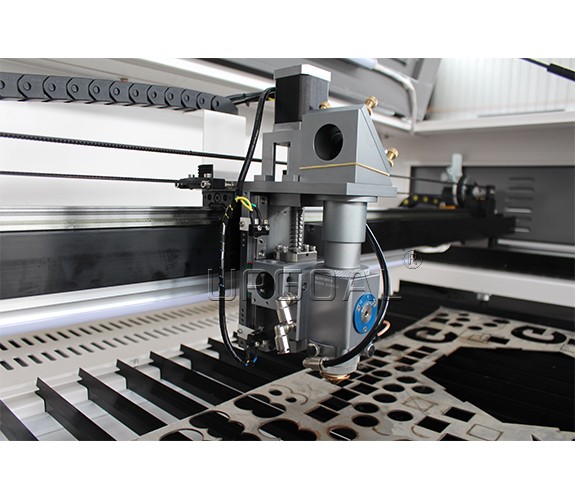

2. Equipped with high preicsion metal&non-metal laser cutting head. Stainless steel, carbon steel, acrylic and wood can be cut.

With ELC 300W combined beam Co2 laser tube( amximum 320W), can for 2mm thickness stainless steel/carbon steel cutting, also can for 20mm wood & 30mm acrylic plate cutting.

3. With advanced embedded RuiDa 6332M DSP real-time laser cutting control system, running faster, laser intensity and speed automatic matching, perfectly realized the consistency of the corner cutting effect

4. Specialized metal cutting using non-contact RuiDa live focusing system, ensuring same cutting quality for whole working table, no need further processing for the fracture section, high efficiency, long life time and more stable.

5. With auto height controller for laser head, can track the metal material surface and adjust suitable focus length, ensuring the cutting quality.

6. Working table:

Honey Comb Table: applicable to various soft materials with good adsorption effect and low reflection ratio.

Knife Strip Table: With oxidation treatment and low reflection ratio Ensured cutting quality

Auto Lifting Table for more thickness materials:Maximum Loading 50kgs with 300mm up-down distance.

7.High- power famous Teyu S&A brand Industrial water chiller CW-6000AH is equipped to ensure the machine can work last long time.

8. Air filter with 5 layers filtration, during the laser engraving cutting machine using, can filtering a mass of gas & smoke which are harmful to human health when engraving & cutting processing materials. Has the feature of low noise, flexible using, and cover small area.

9. Adopting imported focus lens with high luminousness and mirror with high reflection ensure stable power transference and laser beam consistency.

10. Adopt 3phases Yako stepper driver with high dynamic response performance and loading capacity.

11. Belt transmission type. High speed and precision with smooth cutting surface.

12. Rationalized placement of the electronic parts. Optimized heat dissipation effect. Ensured system stability and anti jamming capability.

Effective working area | 1300*900mm |

Laser Type | Combined beam Co2 laser tube |

Laser tube power | 300W, maximum 320W, ELC brand |

Working table | High strength knife strip |

Auto lifting table | Up and down 300mm |

Oxygen control system | Yes |

Laser head | Automatic torch height controller laser head structure for metal materials |

Driver mode | 3 phase stepper motor and driver(Yako) |

Guide rail | Linear square guide rail ( CSK,Taiwan) |

Transmission | Belt |

Control panel | English |

Laser output control | 1-100% software setting |

Engraving speed | 0-60000mm/min |

Cutting speed | 0-10000mm/min |

Control system | RuiDa control system 6332M (Live focusing system) |

Control software | MetalCut |

Design software when delivery | CorelDraw |

Control panel | DSP offline |

Resolution accuracy | < 0.01mm |

Location precision | < 0.01mm |

Highest scanning accuracy | 2500DPI |

Type of cooling | Industrial chiller, CW-6000 (Teyu, S&A) |

Water protection system | Yes |

Blow-off system | Air pump and air blower |

Working temperature | 0-45 °C |

Operating humidity | 5-95% (without condensed water) |

Voltage | AC 220V/110V, 50/60Hz, single phase |

Supporting picture format | PLT、DST、DXF、BMP, DWG、AI、LAS,etc |

Certificate | CE/FDA |