Brief Introduction:

Model: UG-1530WL

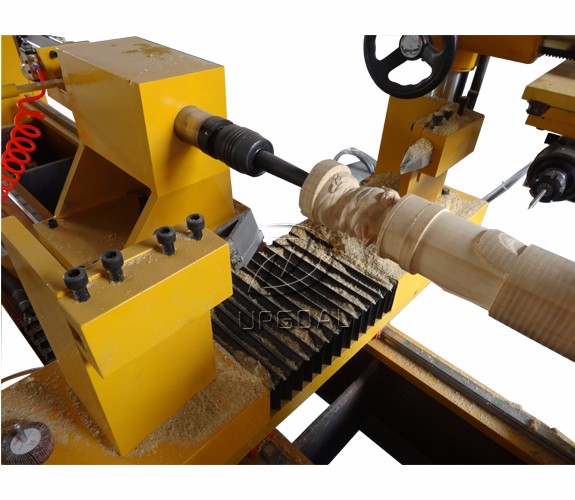

CNC wood turning broaching engraving machine

CNC wood lathe machine

Single axis double blades

Applications

Suitable for handrail, vase,table leg, European style furniture, Roman pillar, wooden clothes hanger & washbasin, kingpost, aisle column, waist drum, solid wood furniture, solid wood stairs, home decoration,wooden decoration, wooden artware,columniform conical, arc-shaped, sphere,ect all kinds of solid of revolution wooden product or semi-finished wooden products.

Materials can be processed: all kinds of wooden materials, such as beech, oak, ailanthus birch,teak, sapele, fraxinus mandshurica, merbau, sandalwood,bubinga, ect.

Features

High efficiency,high surface finish,big diameter turning broaching engraving wood lathe machine

Adopts double blades, one is front, the other is back, 10mm distance between 2 blades in the axis direction, improve the working efficiency. Finish one wood cylinder turning broaching engraving just needs 90s at least.

One time setting multi functional processing, auto switching for turning, broaching, milling spiral surface, curve surface, flat engraving, suitable for complicated beautiful workpiece processing.

Auto changing turning & engraving angle, meet the requirements of big diameter wood cylinder processing

Can adjust each blades turning proportion at random according to processed materials, reducing the workpiece bounce and vibration, increasing the turning wood finish.

Numerical control frequency conversion, energy-saving power, adjusting speed timely, multistage safe protection

Adopting high performance inverter, frequency conversion, step-less speed change, adjusting turning speed timely according to workpiece’s diameter, saving power.

Multistage safe protection, protect motor and machine effectively, ensuring machine working under the normal loading.

USB connection, easily to change the pattern, no need programming at site, system can upgrade

Easy drawing,just draw the easy pattern, then can process, no need complicated programming.

System can upgrade with USB disk file, realizing remote redact and local operation.

Supporting single blade, double blades one time process, no need complicated program to finish multiple different turning, meets with different workpiece requirement, easy and fast.

Pause and memory function, more convenient for inspect workpiece processed quality( precision and finish), timely adjusting.

Specialized CNC control high precision control system, easy to operate, short leaning, no need specialized knowledge, fast processing speed and good uniformity of finished products.

Cast iron machine bed, less deformation and stable transmission

Machine bed’s design & processing is standard according to processing machine norm, adopting one time casting, aging treatment, less deformation, increasing machine using stability.

High performance belt transmission, ensuring workpiece quality and machine life time.

Air cooled electronic control cabinet, lowering the temperature of control cabinet effectively, long time all electronic component life time.

Maximum processing length | 1500mm(or 2000mm/2500mm/3000mm or customzied) |

Maximum turning diameter | 300mm( not for processing diameter, that depends on material, finished product shape and others) |

Air pressure | 0.6-0.8Mpa |

Maximum processing speed | 2000mm/min |

Minimum processing unit | 0.001mm |

Transmission | X, Z-axis : lead ball screw, Y-axis: rack and pinion |

Guide rail | Hiwin, Taiwan |

Spindle turning speed | 0-3000rpm |

Motor power | 4kw |

Spindle power | 3.5kw air cooling |

Universal adjustable bracket | With |

Blades material | Superhard alloy |

Control system | DSP offline |

Motor | Stepper motor |

Driver | Stepper driver, Yako |

Inverter | Best, China |

Drawing Software | AutoCAD |

Hand controller recognize file | *.dxf |

Voltage | AC 380V, +10%, 50/60Hz, three phases or AC 220V, +10%, 50/60Hz, single phase |

Machine size | 3000*1000*1500mm |

Packing size | 3100*1200*1700mm |

N.W | 1500kg |

G.W | 1600kg |

Certificate | CE |