Brief Introduction:

Model: UG-1500LW2000W fiber laserPortable wobble handheld welding headDual wire feedingRelFar laser welding system

Applications & Features

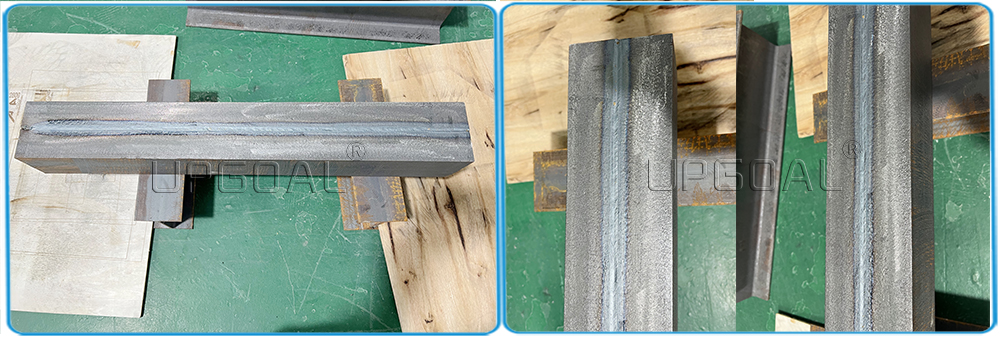

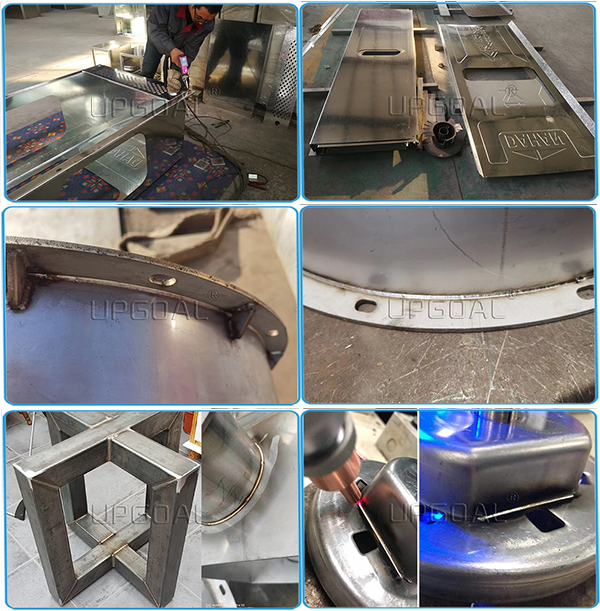

Handheld fiber laser welding machine, uses latest 2000W fiber laser generator. It's equipped with China famous brand wobble weld head. The machines appear to laser equipment industries, fills in the blank of hand-held welding. It has the advantages of simple operation, beautiful welding beam and fast welding speed. Welding in thin aluminum,stainless-steel sheet, iron sheet, galvanized sheet and other metal materials can perfectly replace the traditional argon arc welding, electric welding and other processes.

Handheld laser welding machine can be widely used in cabinets, kitchens, staircases, elevators, racks, ovens, stainless steel doors and windows guardrail, distribution boxes, stainless steel home and other industries complex and irregular welding process.

1.The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

2.High cooling rate, which can weld fine weld structure and good joint performance.

3.Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

4.The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

5.No consumables, small size, flexible processing, low operating and maintenance costs.

6.The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

7. Fast welding speed, 2~10 times faster than traditional welding.

8. Easy operating need no training.

9. Safer, more environmentally friendly.

Main Parts

Fiber Laser source: Adopting famous MAX 2000W the photoelectric conversion rate is greatly improved, laser power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet customer needs.

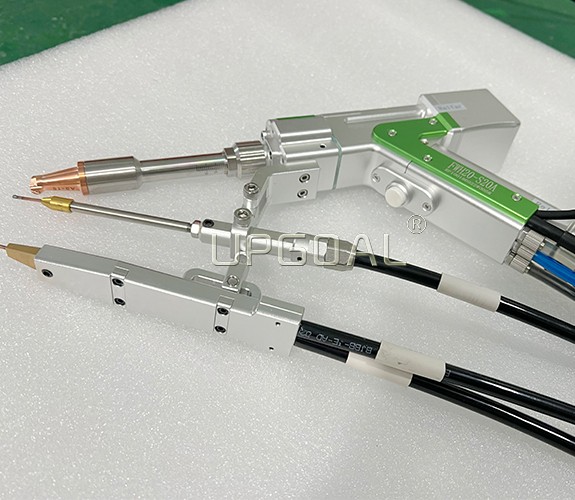

Portable single wobble handheld welding head (RelFar), supports Dual & single wire feeding, Light shape, economic deign, instead of fixed weling head, it offers so much welding convenience for welding big, or heavy or complex structure articles.

With dual Wire feeder( can choose dual or single wire feeding) , in order to make the welding joint full and level and to meet the required mechanical strength requirements. With dual wire feeding, can realize 8mm wobble width, and stacking welding, suitable more thick metal parts.

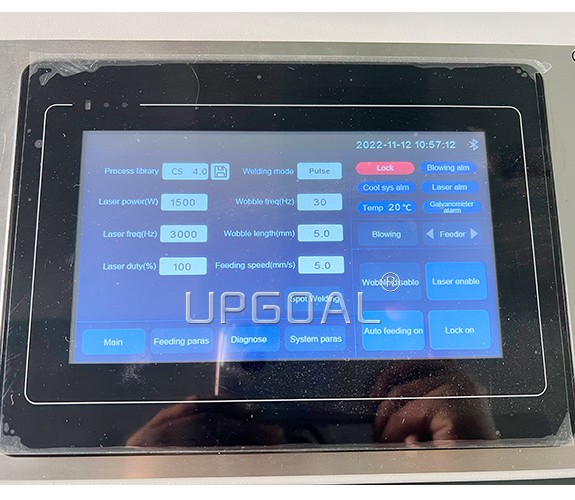

Special laser welding system(RelFar) : Welding software is easily operated as the mode of human-computer interface. Strong software function can be realized by simple touch screen.It has editable and memory functions. and welding width of the processing parts, and solve the disadvantage of minor laser welding spot, and provide better welding forming.

Industrial Water chiller( Teyu S&A RMFL-2000): One of the biggest convenience of the machine is the inside water chiller. It saves a lot of the machine's dimension.It is constant temperature industrial type.

Laser Power | 2000W(MAX/Raycus brand) |

Laser Wave Length | 1070 NM±20nm |

Fiber Length | standard10M Maximum 15M |

Laser Pulse Frequency | 1-20HZ |

Pulse Width | 0.1-20ms |

Adjusted spot range | 0.1-3mm |

Minimum Welding pool | 0.1mm |

Collimating focal length | 50mm |

Focus length | 150mm |

Focus adjustment range | -10mm~+10mm |

Spot adjustment range | 0~5mm |

Gas source | Argon or Nitrogen,≤1Mpa |

Working mode | Continuous or modulate |

Welding head | Portable single wobble handheld welding head(RelFar) |

Welding system | Touch screen control panel(RelFar ) |

Beam quality | M2<1.2 |

Line width | <5nm |

Straight modulate | 0-5KHZ |

Welding speed range | 0~120 mm/s |

Cooling system | Water cooling, industrial water chiller,Teyu S& A brand |

Welding thickness recommendations | 0.5-4mm |

Welding gap requirements | ≤0.5mm |

Working environment temperature | 15~35 ℃ |

Humidity range of working environment | < 70%No condensation |

Working Voltage | AC380V, 50/60Hz, three phases or AC220V, 50/60Hz, single phase |