Brief Introduction:

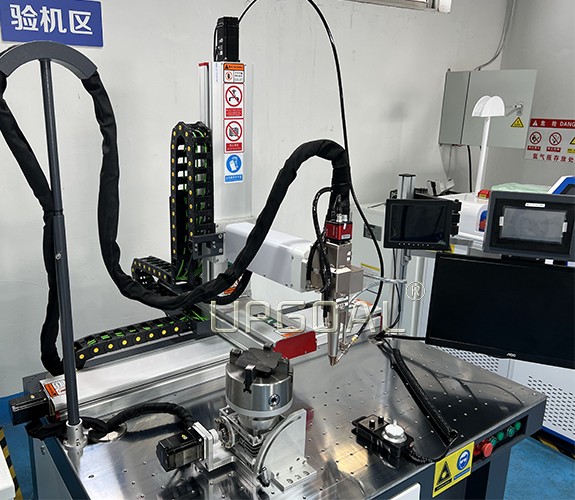

Model: UG-3000LW

platform table moving fiber laser welding

XYZAB 5 axis welding

RayCus 300W fiber laser source

catdsp controller

CCD monitor system

Application

Five-axis linkage laser welding machine, fiber laser welding machine is a kind of laser welding equipment that couples a high-energy laser beam into an optical fiber, and after long-distance transmission, it is collimated into parallel light and focused on the workpiece to implement welding. For the parts that are difficult to access to welding, the flexible transmission and non-contact welding are carried out, which has greater flexibility. The laser beam can realize the splitting of time and energy, and can process multiple beams at the same time, which provides powerful conditions for more precise welding. It is suitable for welding most workpieces, has strong versatility, and has been widely used in hardware equipment and other industries.

Application industry:

The fiber optic continuous welding machine of Umir Laser has a wide range of applications. It is used in the sanitary industry: water pipe joints, reducers, tees, valves, battery industries: lithium batteries,battery packs, laser welding of electrodes, glasses industry: stainless steel, titanium Alloy and other

materials for glasses buckle, precise welding of outer frame and other positions, hardware industry: impeller, kettle, water cup, stainless steel bowl, sensor, diode, aluminum alloy, mobile,etc.

Features

1. The fiber laser welding machine cooperates with the S Y Z automatic platform for welding, industrial PC control, the workpiece can do plane trajectory movement, and the welding graphics are: point, line, circle, square or any plane graphics drawn by AUTOCAD software.

2. The beam quality is excellent, the welding speed is fast, and the welding seam is firm and beautiful, bringing users an efficient and perfect welding solution. It is equipped with a CCD camera monitoring system, which is convenient for observation and precise positioning.

3. Adapt to various complex welds, spot welding of various devices, and welds of thin plates within 1mm;

4. High electro-optical conversion rate and low energy consumption, long-term use can save users a lot of processing costs;

5. The equipment has high reliability and can process continuously and stably for 24 hours, meeting the needs of industrial mass production and processing;

6. The ability to customize the special machine is strong, and the exclusive model can be tailored according to customer needs, and the special automatic fixture can be customized to realize the mass production of products

Fiber laser source | Continuous fiber laser 3000W( Raycus RFL) |

Power adjusting range | 0%~100% |

Platform working area | 1100*600mm |

X-axis travelling | 1280mm |

Y-axis travelling | 780mm |

Z-axis travelling | 780mm |

A-axis travelling | 360° |

B-axis travelling | 360° |

XY,Z,A,W positioning accuracy | ±0.05mm/m |

XY,Z,A,W positioning accuracy | ±0.02mm |

X/Y Maximum linkage positioning speed | 20m/min |

W axis turning speed | 30r/min |

Positiong system | Red light |

Protective gas method | coaxial protection |

Optical output interface | QBH |

Welding thickness | 0.3-6mm |

Voltage | AC380V/220V±10%,3 phases |

Output method | Continuous |

Laser center wavelength | 1080±5nm |

Working humidity | <70% |

Water flow | 2L/min+18L/min |

Working temperature | -10℃~40℃ |

Total power | 11kw |