Brief Introduction:

Model: UG-2260FL

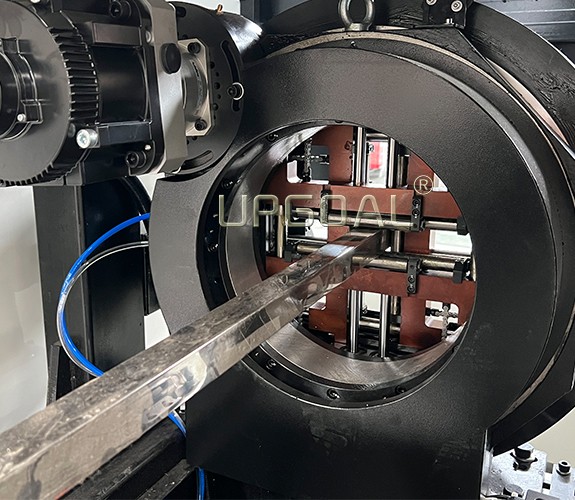

Clamping chuck diameter 245mm

Cutting length 6000mm

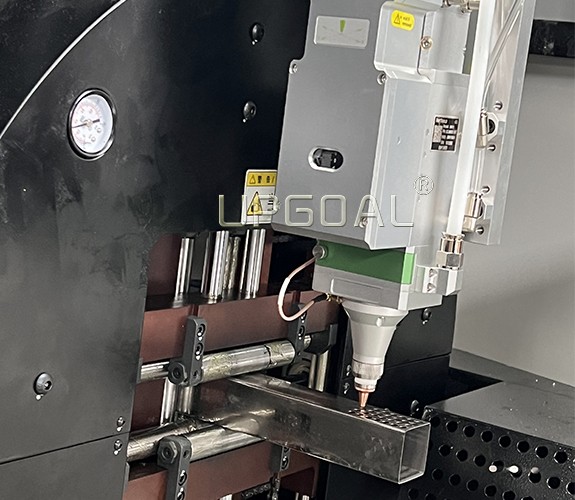

RayTools BM111 auto focusing head

CypCut 3000S sytem

Profile/Tube/Rectangle tube/H beam tube/C-section steel/Angle steel

Application

It is suitable for various special-shaped pipes such as round pipes, square pipes, rectangular pipes, oval pipes, etc.Professional for cutting carbon steel tube, stainless steel tube, galvanized tube, electrolytic tube, silicon steel a variety of thin metal metarials.

Application Industry

Industry of kitchen ware, lamps and lanterns, panel beating, metal cabinets, auto parts, refrigerators, air condition, elevators, hotel metal supplies processing, etc.

Applicable materials:

Used for cutting various metal materials such as carbon steel, low carbon steel, galvanized steel, stainless steel, brass, aluminum, gold, silver, titanium, spring steel and copper can be flexibly processed round pipes, square pipes, rectangular pipes, elliptical pipes and special-shaped pipes, etc.

Features

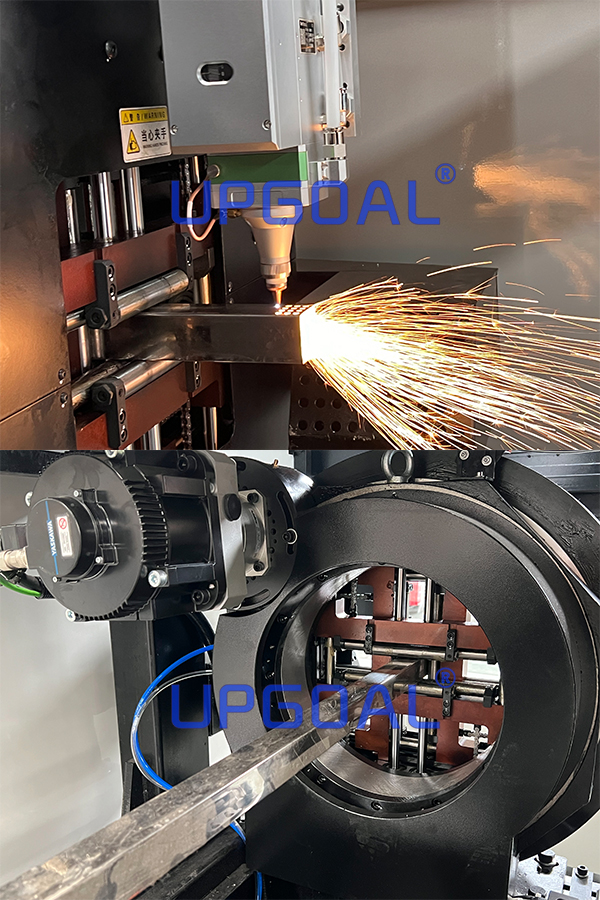

UPGOAL tube fiber laser cutting machine is specially designed for metal tubes with superior performance and simple operation. The tube fiber laser cutting machine has good cutting quality and cutting efficiency. It uses the strong heat generated by the high-density laser beam to irradiate the surface of the material to realize the cutting of metal pipes. Its standard diameters are 220mm, 160mm, 320mm, and the standard length is 6m. Other sizes can be customized.

(1) Strong compatibility, can be flexibly applied to cutting metal round pipes, square pipes, rectangular pipes, special-shaped pipes, etc., and can process any graphics and patterns.

(2) High precision, fast speed, narrow cutting seam, small heat-affected zone, smooth cutting surface without burrs.

(3) Non-contact cutting, with auto focusing RayCus BMH110 laser cutting head will not touch the surface of the material and scratch the workpiece.

(4) Fully automatic chuck adopts dual pneumatic mode to automatically fix the pipe to avoid possible displacement during the cutting process and ensure cutting accuracy.

(5) Adopted stable RAYCUS/MAX brand 1000W-6000W fiber laser source, photoelectric conversion rate is high, high beam quality, work life of more than 100,000 hours, no maintenance costs.

(6). The CypCut 3000S & TubePro & Tubes T-Lite control system is embedded with a rich memory of laser cutting setting references, flexible layout designs and tool path editing, data import/export,bridging, coedge, beam compensation, curve smoothing, division, caombination, automatic identification of exterior and interior modes and so on, compatible, with laser source brands such as IPG, SPI, JK, Raycus, etc.

(7). Adopted Fuji Japan 1300W 850W servo motor and driver for XY axis, rotary axis with 1.8KW/1.3KW the servo motor with SHIMPO reducer, more accurate, It realizes closed-loop control of position, rotating speed is more faster, general rated speed can reach 2000~3000 rpm; With high strong anti-overload capability, and smooth operation at low speed, no stepping operation similar to stepper motor when running at low speed.

(8) Teyu S&A Industrial chiller , ensuring fiber laser and laser head can be cooled quickly to ensure that the laser machine has stable power even working at high temperature, high efficient and fast operation.

(9) Adopted SMC Japan proportional valve, improve cutting accuracy.

(10) The slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is small, and there is no mechanical deformation.

(11)Suitable for a variety of materials, and can cut steel plates, stainless steel, aluminum alloy plates, hard alloys and other materials of any hardness without deformation.

(12) High-quality automatic cutting heads, stable laser generators, reliable transmission systems, servo motors and drives imported from Japan, and Schneider electrical components imported from Germany all play a very important role in the operation of the machine.

Model | UG-2260FL |

Cutting diameter | φ20*20-φ240*240mm |

Cutting length | 6000mm |

Laser type | Fiber laser generator |

Laser working medium | Fiber |

Laser wavelength | 1064nm |

Cutting head | RAYTools BMH111 auto focusing pointed tip |

Rated output power | 1000W/1500W/2000W/3000W/4000W/6000W(MAX/RAYCUS brand) |

Laser cutting system | FCUT3000S |

Driving system | Fuji/Yaskawa Japan servo motor 1300W/850W 2900W/1800W |

Reduction gear | SHIMPO, Japan |

Guide rail | Linear square guide rail, Hiwin, Taiwan,diameter25mm |

Transmission system | Helical rack and pinion transmission, YYC, Taiwan |

Proportional valve | SMC, Japan |

Straight axis positioning accuracy

| ± 0.01-0.05mm/m |

Straight axis re-positioning accuracy | ± 0.01-0.05mm/m |

Cutting precision can be reach | ±0.2mm |

Maximum travelling speed | 100m/min |

Maximum acceleration | 1.5G-1.8G |

Power supply | AC380V, 50/60Hz, three phases or AC220V, 50/60Hz, single phase |

Graphic format supported | CAD,DXF, etc |

Lubrication system | Automatic |

Working environment | Temp:0-40℃,humidity:≤80%,No condensation |

Machine size | 9250*2100*2150mm |

Weight | 3000kg |

Certificate | CE/FDA |