Brief Introduction:

Model: UG-1290L

CCD camera Co2 laser cutting machine

Leetro control system

For cloth trademark, logo, batch precision cutting

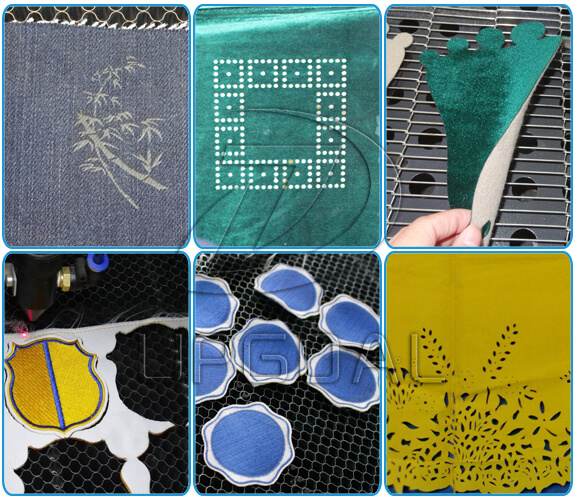

Applications

A variety of fabrics can be cut into any graphics precisely which can be made into Sofas, tents, umbrellas, clothing, leather, soft cloth (cloth, leather, plush), car interior (seat covers, floor mats, cushion).

Features

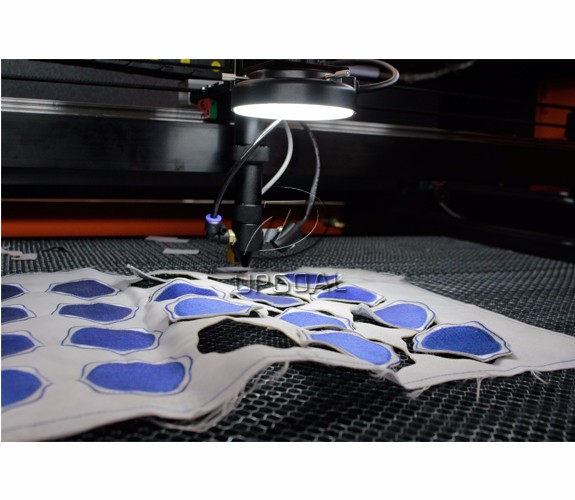

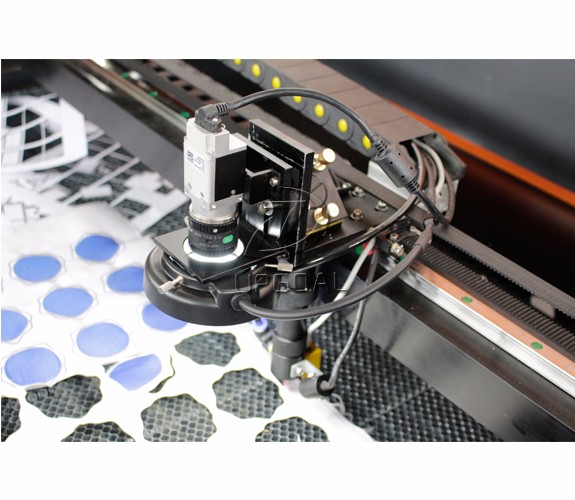

CCD camera system

1. Imported Japan 13 million pixel high precision identification system, specially suitable for automatically material identify positioning cutting.

2. Has the feature of positioning continuous cutting, automatically draw the outline and then cutting, ensuring the whole material high speed & high precision cutting.

Laser Head

Newly design, More in according with mechanical engineering. Safe and Durable. Simple Operation with high engraving/cutting speed and high laser power convert ratio.

Laser Tube

Adopted famous Reci W2 Co2 laser tube, rated power: 90W, peak power: 100W, long time time and stable

Working Table

Honey Comb Table: applicable to various soft materials with Good adsorption effect and low reflection ratio.

Knife Strip Table: With oxidation treatment and low reflection ratio Ensured cutting quality

Auto Lifting Table for more thickness materials:Maximum Loading 50kgs with 300mm up-down distance.

Beam Path System

Adopting imported focus lens with high luminous and mirror with high reflection ensure stable power transference.

Motion System

Imported High precision,low friction force and stand wear and tear guide rails and blocks with 3M belt ensured stable transmission, lower noise

Operation System

Specialized Leetro MPC6595C2 CCD control system, advanced USB port DSP control system with large inner memory device and Fast curvilinear cutting and Optimized shortest path function, Greatly improved the working efficiency .

With full-process automatic laser power attenuation compensation , ensuring the performance consistency of engraving/cutting. The High speed motion control program with pee-buffering function enhances productivity more.

Specialized Visual positioning laser cutting control system for fabric logo /outline cutting with Leetro MPC6595C2 CCD control system

Completely compatible with various CAD&CAM softwares such as AuotCAD, CorelDAW, supporting the designs directly exporting. With advanced Color management and defining the working turns with different colors , All or a part work can done in one time.

Rationalized placement of the electronic parts. Optimized heat dissipation effect.

Cooling System

Industrial chiller CW-3000, ensuring the laser tube long time continues working

Effective working area | 1200*900mm |

Laser Type | Co2 sealed-off laser tube |

Laser tube power | W2 series, Reci, Beijing (Rated power: 90W, max. Power: 100W) |

Laser head | with Japan CCD camera, Computar brand |

Working table | Honey comb and knife strip, double working tables, |

Driver mode | 3 phases stepper motor and Driver, Yako brand |

Guide rail | Linear square guide rail ( Hiwin,Taiwan) |

Transmission | Belt transmission |

Control panel | English |

Laser output control | 1-100% software setting |

Engraving speed | 0-60000mm/min |

Cutting speed | 0-10000mm/min |

Control system | Leetro MPC6595C2 |

Control software | Visual positioning laser cutting control system V2.0 |

Design software when delivery | CorelDraw |

Control panel | DSP offline |

Resolution accuracy | < 0.01mm |

Location precision | < 0.01mm |

Highest scanning accuracy | 2500DPI |

Type of cooling | Industrial chiller, CW-3000 cooling |

Water protection system | Yes |

Blow-off system | Air pump for the laser head Air blower for the machine |

Working temperature | 0-45 °C |

Operating humidity | 5-95% (without condensed water) |

Supporting picture format | PLT、DST、DXF、BMP, DWG、AI、LAS,etc |

Voltage | AC 220V+10% 50/60Hz, single phase |

Certificate | CE/FDA |