Brief Introduction:

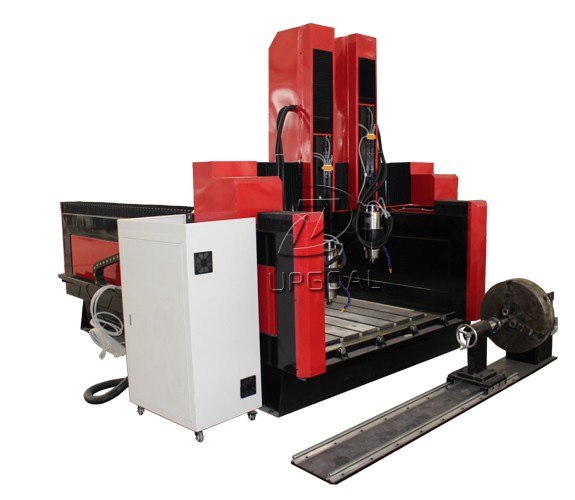

Model: UG-1325-2

double Z-axis with 5.5kw water cooling spindle

Heavy duty stone cnc router

1300*2500*550mm

Stainless steel water slot cooling

4th axis diameter 400mm

Applications

Mainly used for natural marble, granite, artificial stone, tombstone, milestone, tile, glass, bluestone,sandstone, crystal, microlite,mural, village tablet inscription, decoration skirting line,...such relief engraving, singlet line, character, flat pattern engraving, with rotary axis, can for stone cylinder,breast board, handrail, dragon columns,figure of Buddha...engraving.

Features

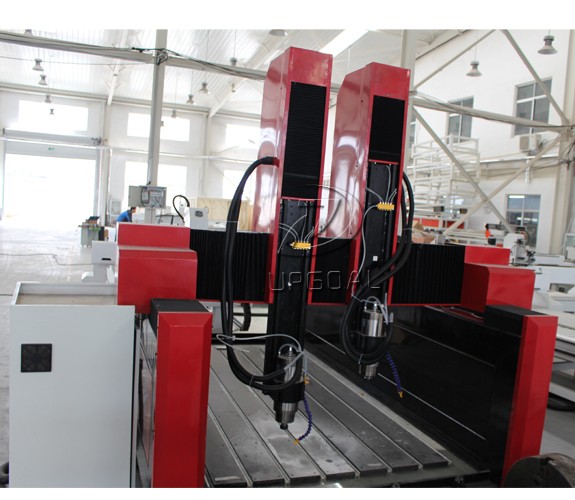

1.Adopted T type steel machine bed, strong rigidity, strong dynamics, ensuring the machine long time high speed moving and no deformation. Integrated stainless steel water slot with working table & machine body more convienient for water collection and circulation.

2.4th axis rotary axis, diameter 400mm, working length 120mm for stone cylinder carving.

3.XYZ-axis adopted imported Hiwin, Taiwan linear square guide rail, high precision,fast speed and good wear resistance.

4.Heigh precision helical rack and pinion transmission for XY-axis,fast speed and powerful. Z-axis with double nut lead ball screw transmission, good weight capacity and stable moving.

5. Dual independent Z-axis with Powerful 5.5kw water cooling spindle, easy to engraving all kinds of stone, not only fine engraving, but also the bottom smooth and clear.

6.China famous stepper motor and driver for XYZA-axis, high precision, faster speed and more stable. Dual motor and driver for Y-axis,ensuring the stable moving.

7.Optioal PCI NcStudio/MACH3/DSP offline/NK105 4 axis control system

8.Bothway tools cooling system, effectively improve tools life time.

9.Special dustproof, waterproof device, effectively keep the transmission part cleaning and rust protection, more easy maintenance.

10. Semi-auto lubrication sysetem, more convenient and easy for whole machine lubrication.

11. Auto tool calibration, accurate and convenient for Z-axis 0 point setting.

12.Special several processing 0 point saving method.

13.Memory of break point and power failure,ensuring continue working after breaking point or next time processing.

14.Advanced file processing function, can timely correct faults, and good compatibility for Type3/Artcam/Mastercam/Caxa such file. Advanced three dimensional curve forcast algorithm, stable broken line, ensuring the curve moving speed & precision.

Effective working area | 1300(X)mm*2500(Y)mm*550(Z)mm |

| 4th axis rotary axis | Diameter 400mm, working length 1200mm, reduction gear transmission |

Materials | Strong T type steel pipe structure |

Working table | Aluminum T slot |

Cooling system | Stainless steel water slot cooling |

Moving type | Gantry moving |

Guide rail | Linear square guide rail ( Hiwin, Taiwan) |

Transmission | Helical rack &pinion for X Y -axis, Lead ball screw for Z-axis |

Driving mode | Stepper motor and driver for XYZ-axis |

Spindle motor | 5.5kw water cooling, ER25 |

Spindle speed | 0-24000rpm |

Inverter | Sunfar |

Voltage | AC 380V±10%, 50/60Hz, three phases |

Traveling speed | >28000mm/min |

Engraving speed | >15000mm/min |

Machine accuracy | 0.03mm |

Control system | PCI NcStudio/MACH3/DSP offline/NK105 offline |

Suitable software | Artcam, Type3, Ucancam V9,etc |

Carving Instructions | G code *Uoo *mmg *plt HPGL |

Running environment temperature | 0-45 ºC |

Relative humidity | 30%-75% |

Lubrication system | Semi-auto |

Tool calibration | Auto |

Certificate | CE |