There are mainly two types rotary cnc router in the market nowdays. One type is 3 axis rotary cnc router,the other is 4 axis rotary cnc router. If we need a rotary cnc router, how to select? This Article will tell you.

1.3 Axis rotary Cnc router.

3 Axis rotary Cnc Router as its name it is consist with 3 axis such as XYZ or Rotary Axis, Y&Z. The control system is 3 axis type control system. Such as Richauto DSP A11 Please see the following video

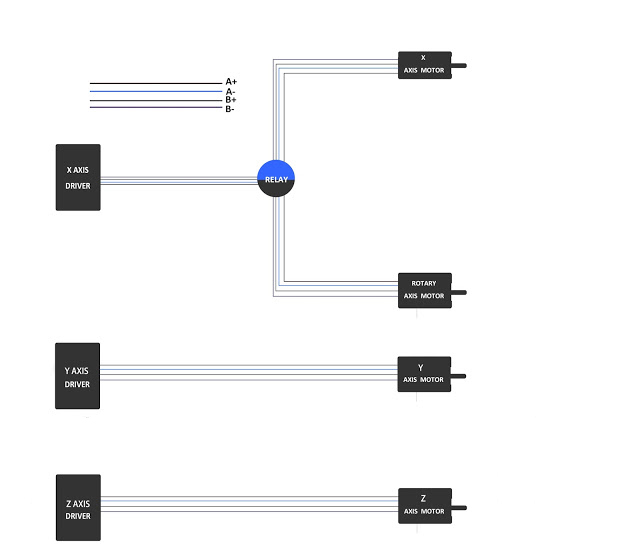

From the video we can see while working, there are only 3 axis with movement.It is : Rotary, Y axis and Z axis. Follow is a simple diagramm for better understanding.

When the rotary is working. The X axis Driver is connected with Rotary Motor instead of X axis. So there will be no movement of X axis motor. So it is not a fault if rotary is running and X axis keep still.

Since

there is no movement on X axis, the 3 axis type cnc router only can do

regular cylinder engraving.If we want to do complicated cyliner

engraving such as with flat 3d engraving then we need to use 4 axis

rotary cnc router. Reference working sample as following:

2.4Axis Rotary Cnc Router

Rotary

of 4axis rotary Cnc Router is with its own driver.Its no need to make

changes in driver connection if need rotary work. And the 4 axis, XYZ

and Rotary can work simultaneously.It is suitable for more complicted

cylinder 4d engraving. Followings is a 4 axis machine working video. The 4 axis system mostly used are RichAuto DSP A18, NK-105 and NK-260.

Most 4 axis rotary cnc router are with multi spindles and rotary for increasing the working efficency.

4axis rotary cnc router is more expensive than 3 axis rotary cnc router. Selecting which type is determined by the work requirement.