There are mainly two types rotary cnc router in the market nowdays. One type is 3 axis rotary cnc router,the other is 4 axis rotary cnc router. If we need a rotary cnc router, how to select? This Article will tell you.

1.3 Axis rotary Cnc router.

3 Axis rotary Cnc Router as its name it is consist with 3 axis such as XYZ or Rotary Axis, Y&Z. The control system is 3 axis type control system. Please see the following video

from the video we can see while working, there are only 3 axis with movement.It is : Rotary, Y axis and Z axis.

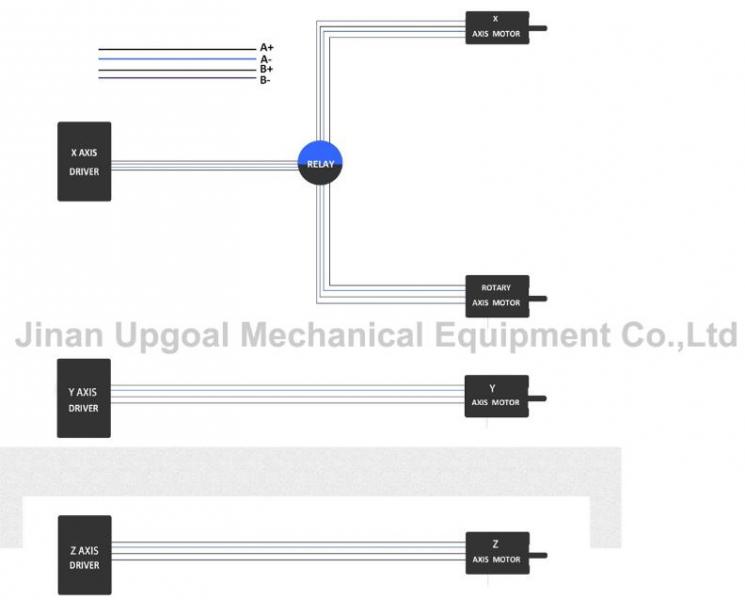

When the rotary is working. The X axis Driver is connected with Rotary Motor instead of X axis. So there will be no movement of X axis motor. So it is not a fault if rotary is running and X axis keep still.

Since there is no movement on X axis, the 3 axis type cnc router only can do regular cylinder engraving.If we want to do complicated cyliner engraving such as with flat 3d engraving then we need to use 4 axis rotary cnc router.

2.4Axis Rotary Cnc Router

Rotary of 4axis rotary Cnc Router is with its own driver.Its no need to make changes in driver connection if need rotary work. And the 4 axis, XYZ and Rotary can work simultaneously.It is suitable for more complicted cylinder 4d engraving.

Most 4 axis rotary cnc router are with multi spindles and rotary for increasing the working efficency. As below video shows:

4axis rotary cnc router is more expensive than 3 axis rotary cnc router. Selecting which type is determined by the work